System specification, design, simulation, procurement

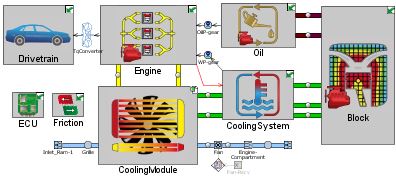

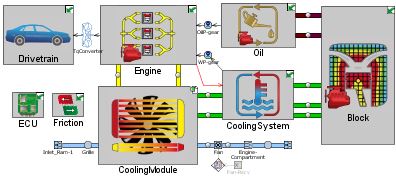

PTL is routinely involved in the specification and design of cooling circuits for engines and other machinery. These often involve the creation of simulation model of the whole circuit, including pump, actively controlled thermostats, radiators and heat exchangers and confirming correct operation over a range of temperatures, pressures & flow rates. These activities are quite key, as the size of the various system components impacts:

- Vehicle packaging

- Engine warm up time and parasitic losses

- Transient and steady state temperatures

Our software can model and track the heat originated in the combustion chamber, moving through the engine structure into the cooling circuit and eventually into the vehicle air under the bonnet (hood) through the vehicle radiator.

This type of analysis is not only confined to vehicles and internal combustion engines. It can also be applied to other machinery and systems, including Combined Heat and Power (CHP) units and their interaction with buildings

When complicated fluid and heating flows need to be evaluated, including their effects on heat transfer and temperatures in the structure, 3D analysis tools, like FEA and CFD software can be brought in support.